commutator.info

The program “commutator.info”

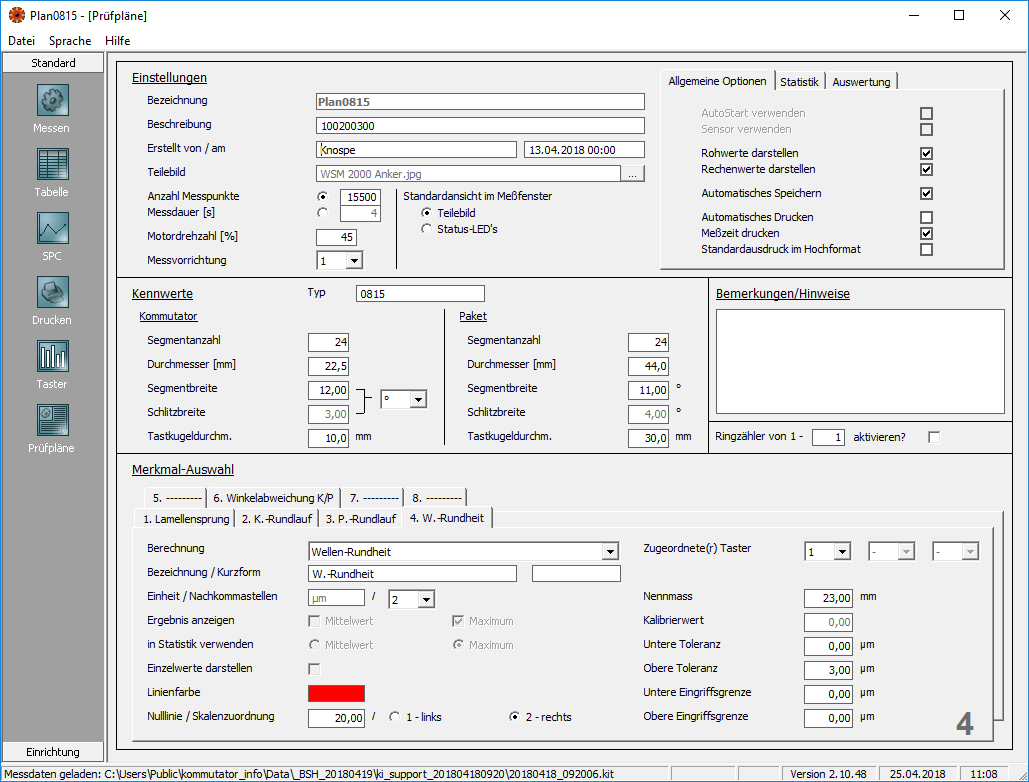

determines the geometric parameters of electric motor rotors, e.g. the segment gap, form deviation etc. The program has been completely redeveloped.

The basis for this program is years of experience in this area, gathered through daily experience with the earlier program versions “Kommutat32” and “UniMessSPC”. Many customer suggestions and requests have been included in this new version.

FUNKTIONEN

Measurement of the geometric features of electric motor components

Commutator:

- True running

- Segment gap (Lamella gap) using various analysis methods

- Form deviation of segments

- Concentricity

- Diameter

Shaft, Worm drive:

- True running

- Concentricity

- Diameter

Package:

- True running

- Diameter

Commutator – Package:

- Angular deviation / Angular torsion

More Functions

- Determine up to 8 features per test object

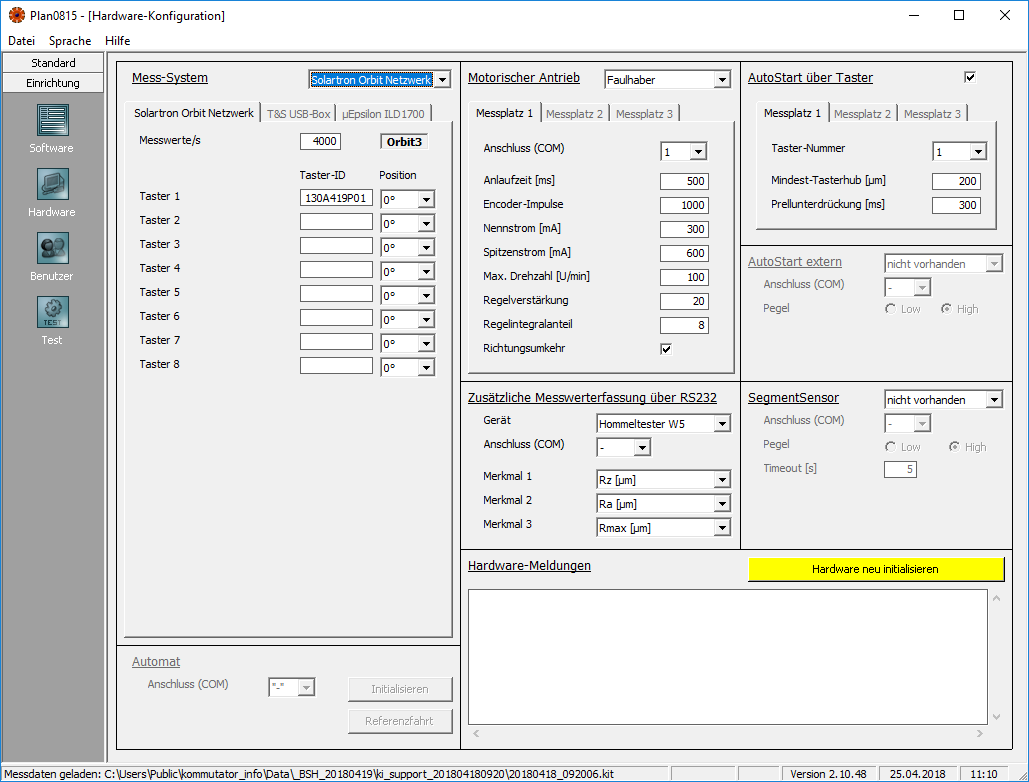

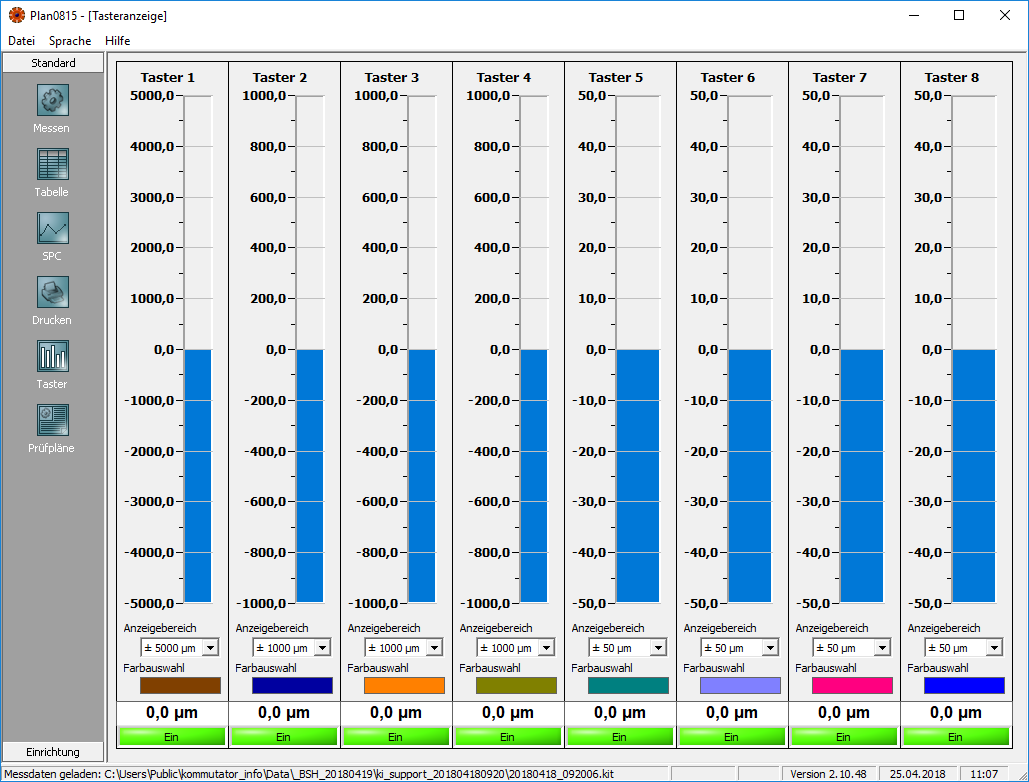

- Measurement data can be acquired with up to 8 (or 16) length measuring probes

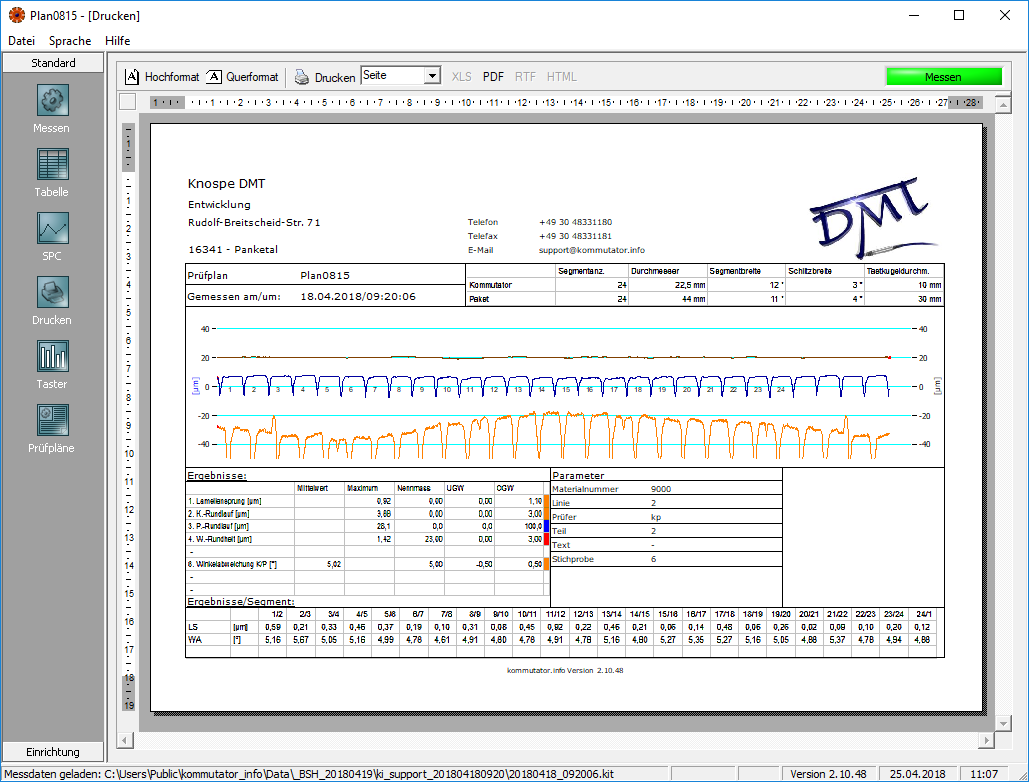

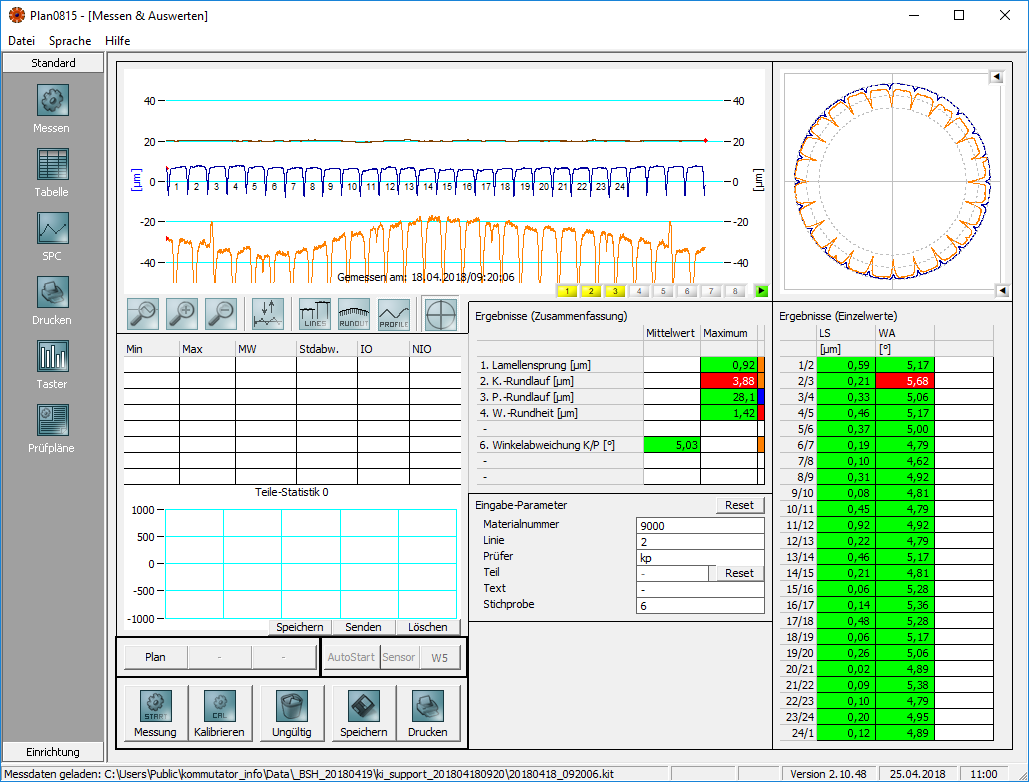

- Graphical display of the commutator contour as animated picture or circle diagram

- Toggleable display of compensation lines, segment borders and the true running curve(s)

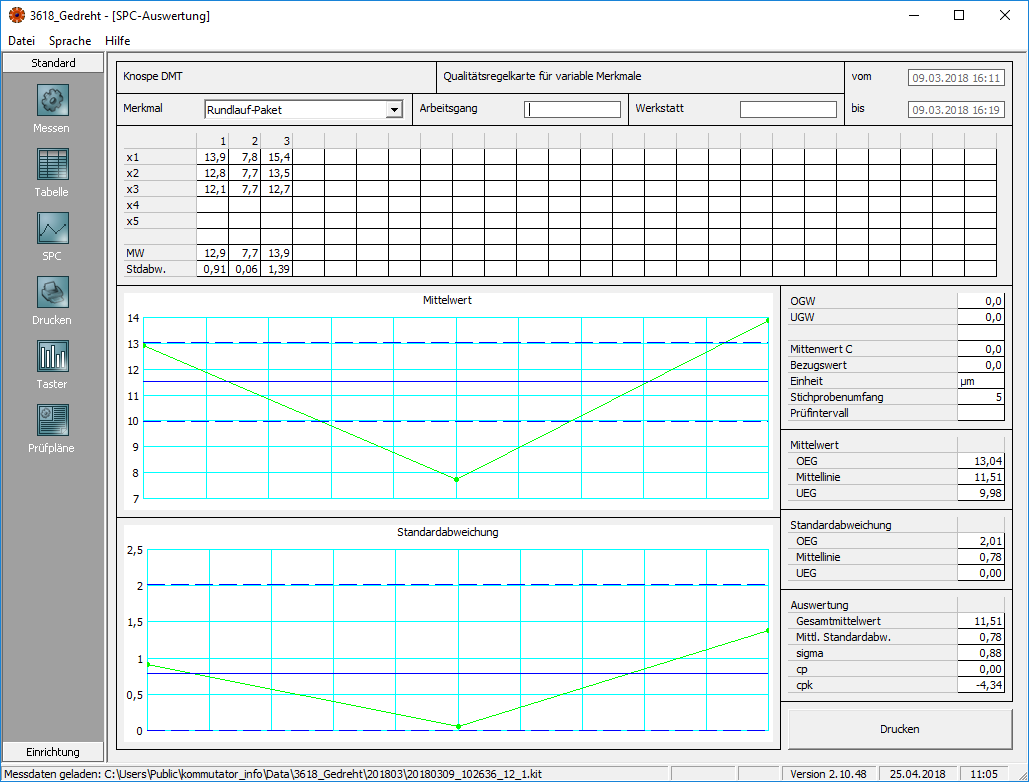

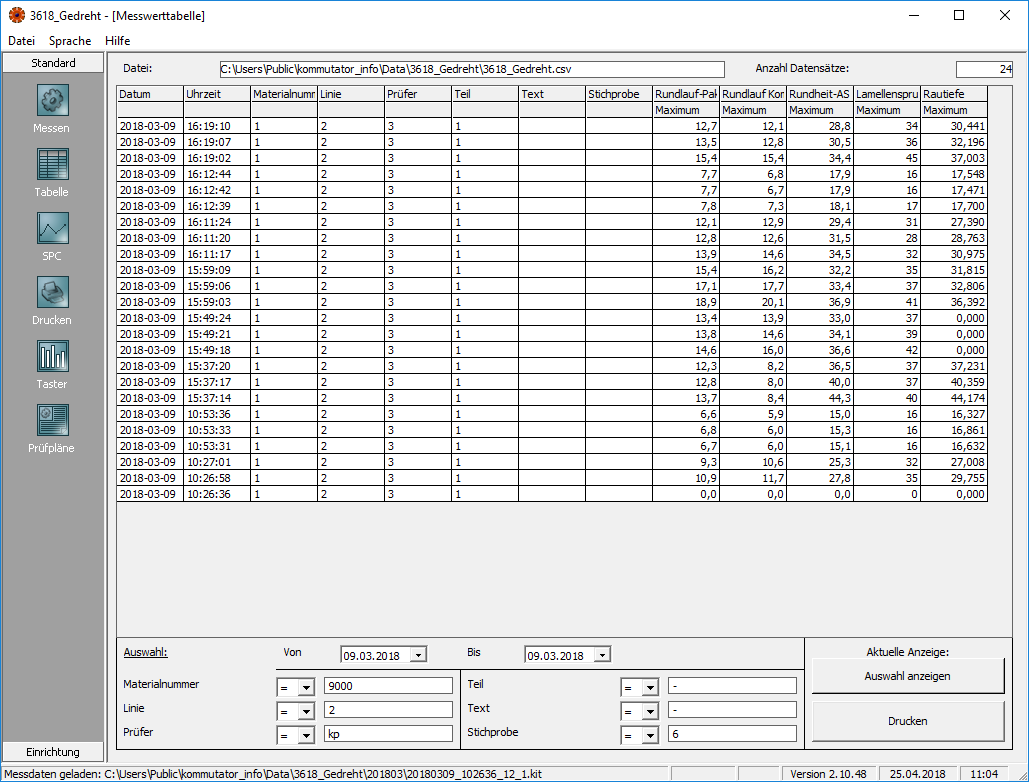

- Analysis results are summarized in tabular form as average or maximum values

- Test results for individual segments can be displayed

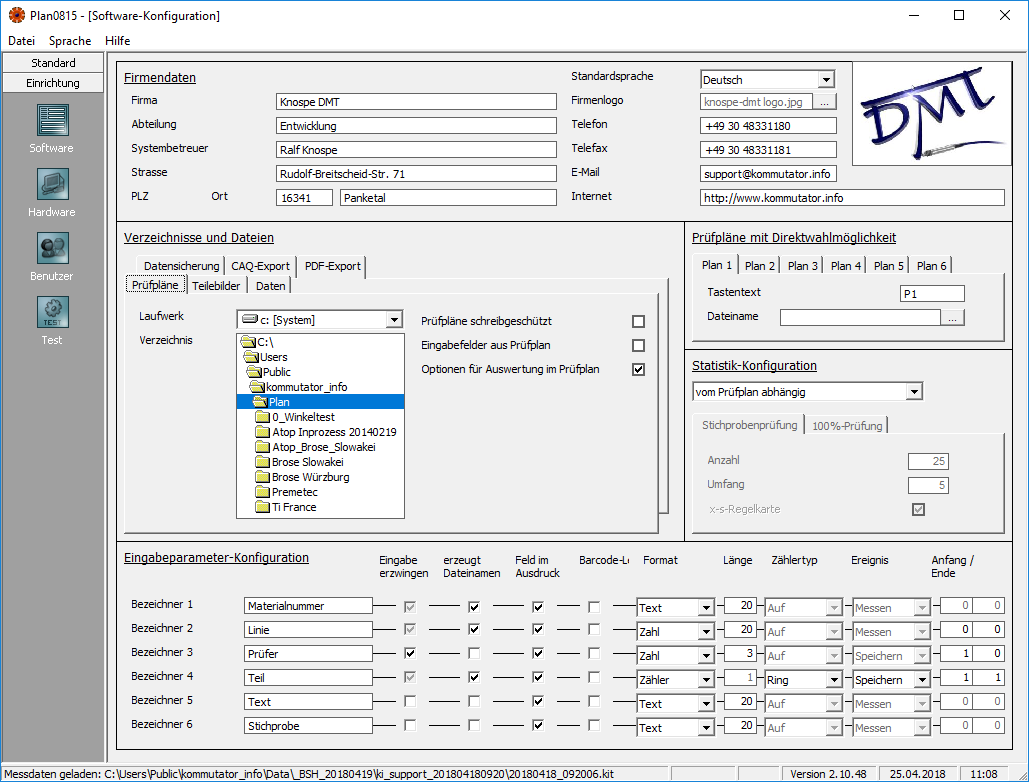

- Test plans for specific components can be created, stored and loaded

- Tabular display of all tests in the current test plan

- Results can be filtered according to date/time and content of the user fields

- Test results can be stored in different formats (Text, PDF etc.)

- Test results can be printed

- Test results can be exported to external CAQ systems

- The test process can be automated (AutoStart feature, SPS control)

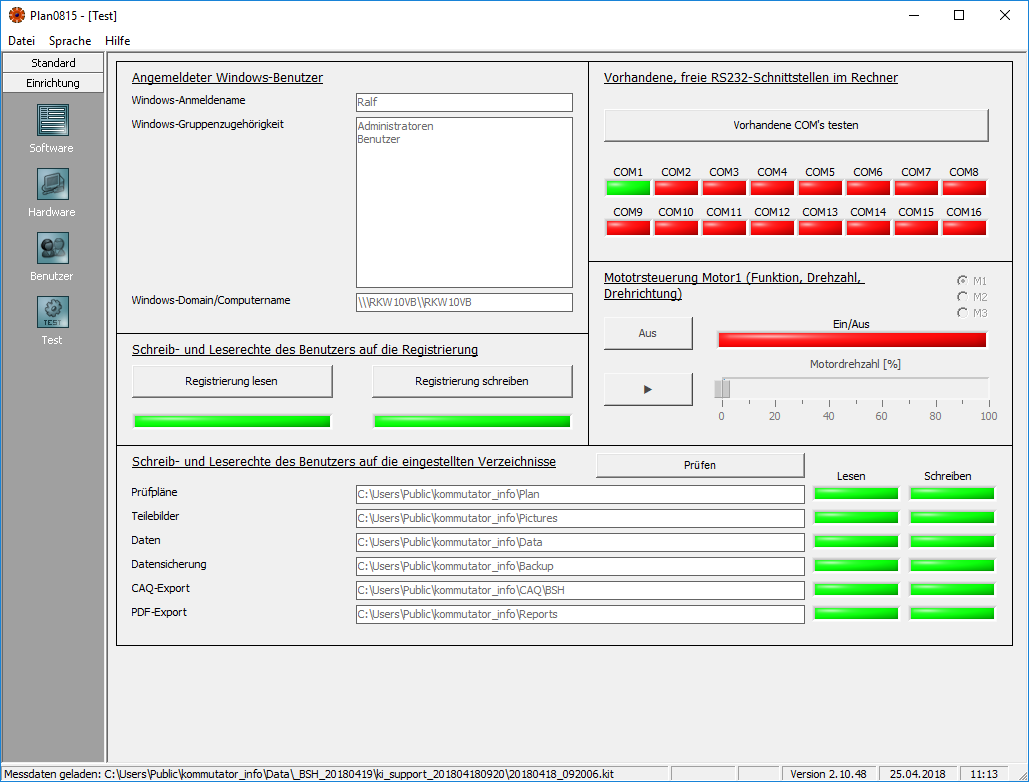

- Simple, feature-rich configuration possibilities for customizing the program according to the wishes of the user

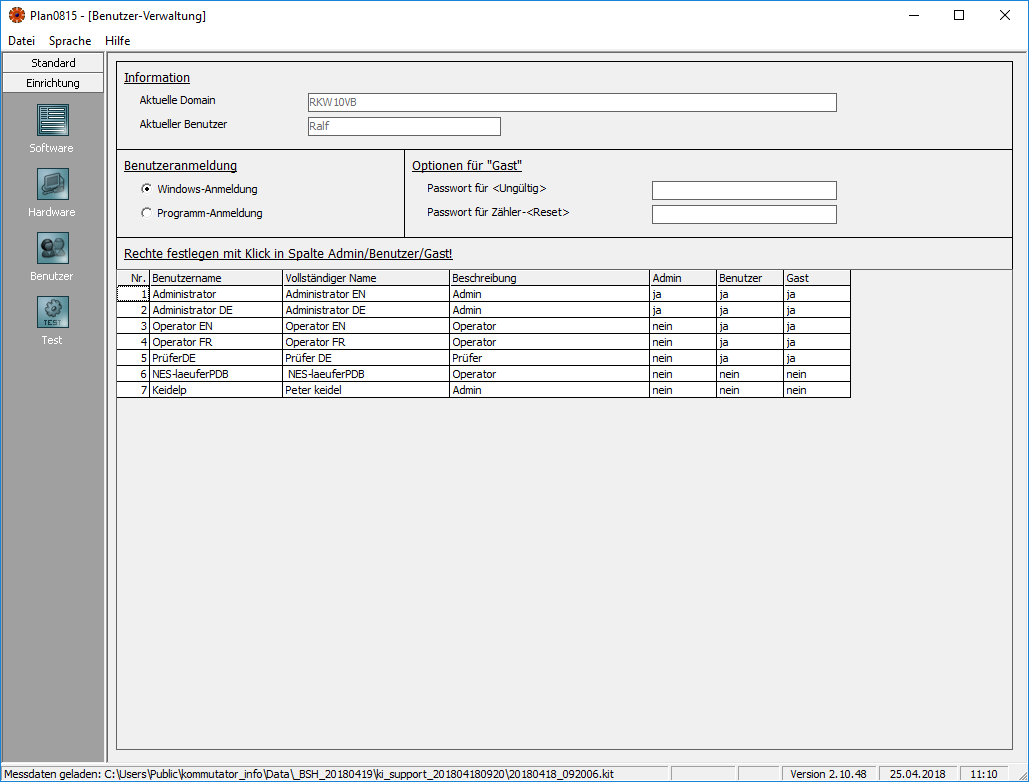

- Allocation of user-rights allows particular features (e.g. Configuration) to be disabled for certain users

New Functions

- Measurement of roughness parameters with optional roughness tester integrated in measuring process.

- Measurement of torsion angle between commutator and package (using tactile or laser sensors).

- Contactless measurement of commutator features with laser sensor.

commutator.info

PROGRAM VERSIONS

The program is available in four versions depending on the tasks to be performed. Optional program extensions are also available.

Basic Version

As described under “Features”, although capture of angular deviation must be ordered as an extra option.

Developer Version

The same as the “Basic” version but with the ability to perform comparison measurements, e.g. in acceleration tests, allowing important product development questions to be answered.

In-Process Version

The same as the “Basic” version, but with the capability to exchange signals with an SPC unit allowing the measurement process to be automatically started and good/bad results to be gathered. The analysis routines have been specially optimized to allow 100% testing of commutator features within a cycle time of >= 5 Seconds.

Measurement Station Version

The same as the “Basic” version, but allowing the connection of up to 16 measuring probes. These can be distributed between up to 3 separate measuring devices. This allows sample-based testing on multiple production lines without retooling.

optional available

Program extensions

-

SPC with x-s rule table for every configured feature

-

A barcode reader can be connected for choosing test and entry of test object information

-

Roughness measurement with the Hommeltester T500/T1000 integration of these results into the program test results

-

Determining the angle difference/torsion between the commutator and the housing

-

Determining the orthogonality of the commutator and shaft in front-side commutators

USER

These companies use commutator.info

-

GERMANY

- Bosch Siemens Hausgeräte GmbH, Bad Neustadt

- Bühler Motor GmbH, Nürnberg

- C. & E. FEIN GmbH, Schwäbisch Gmünd

- FHP Motors, Oldenburg

- Hilti GmbH, Kaufering

- Kaut & Bux GmbH, Dornstetten

- Kaut & Bux GmbH, Herrenberg

- Metabowerke GmbH, Nürtingen

- Miele Werk Euskirchen, Euskirchen

- NIDEC MOTORS & ACTUATORS GmbH, Bietigheim-Bissingen

- Papst Elektromotoren GmbH

- Pierburg AG, Hartha

- Robert Bosch GmbH, Bühl

- Robert Bosch GmbH, Bühlertal

- Robert Bosch GmbH, Hildesheim

- Robert Bosch GmbH, Leinfelden

- Robert Bosch GmbH, Sebnitz

- Siemens AG, Würzburg

- TZO GmbH, Leipzig

-

INTERNATIONAL

- AFCO, USA

- Bosch Automotive Products Co. Ltd., VR China

- Bosch, Corea

- Brose, Tschech Republik

- Brose Automotive La Suze SAS, France

- Brose do Brasil Ltda., Brasilien

- Brose Mexico, Mexiko

- BSH Drives and Pumps s.r.o., Slovakia

- Buehler Motor, Mexiko

- Buehler Motor s.r.o., Tschech Republik

- Buehler Motor Zhuhai Ltd., VR China

- Kolektor Idrija, Slowenia

- Robert Bosch Ltda., Brasil

- Robert Bosch, Mexiko

- Robert Bosch POWER TOOL Kft., Hungary

- Robert Bosch Tool Corporation, USA

- Scintilla AG, Switzerland

- Shanghai Brose Electric Motors Co. Ltd., VR China

- Siemens VDO Automotive, USA

- TI Automotive, France

Contact

btb metrology d.o.o.

Prizrenska 19

85340 Herceg Novi

Montenegro

Telefon: +382 68 173709

E-Mail: info@btb-metrology.com